On August 1st 2019 BRCGS launched Global Standard for Packaging Materials Issue 6. Not only has the name changed, but also key protocol. Despite the changes being announced on the 1stof August, businesses will not be audited against the new version until February 2020. This allows you to prepare your business for the upcoming changes. The new issue includes six major changes consisting of two important changes regarding protocol and four key changes concerning the requirements of the former Issue 5 certification.

With nearly 4,500 certified sites, BRC is the most used global standard designed for the packaging industry. The scope is wide and covers everything from packaging manufacture to printing and the production of materials, with a particular focus on functional and product quality.

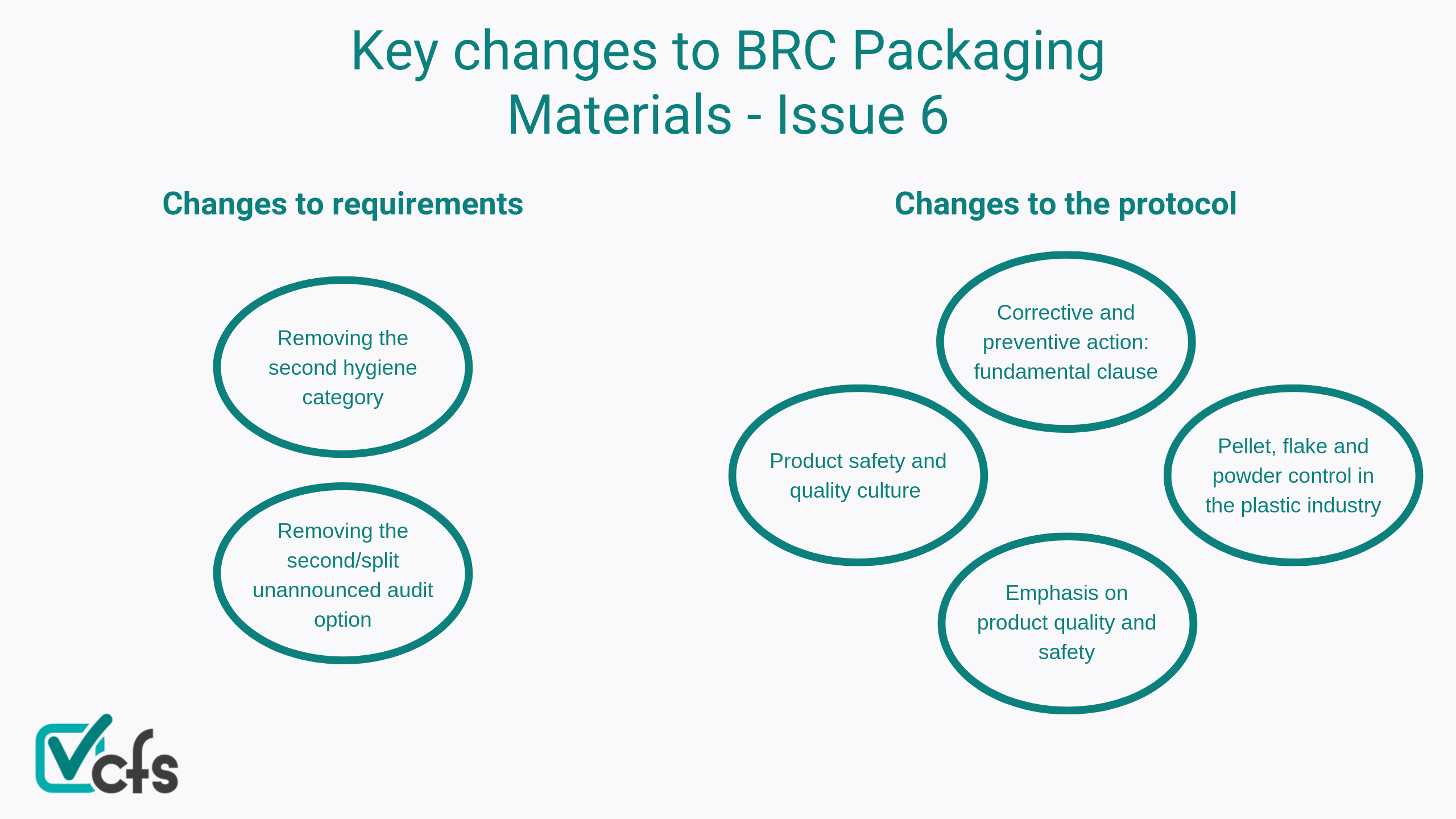

Key Changes to the Protocol:

- Removal of the second hygiene category. On the previous issue, levels of hygiene were split into two categories – high hygiene and basic hygiene. The removal of the two-category system makes the new issue much simpler. Rather than the two tier hygiene levels, it is replaced with a risk-based approach, dependant on only one set of requirements.

- The second change to protocol is the removal of the second/split unannounced audit option. In Issue 5, packaging offered three audit options: Full announced audit, full unannounced audit, and split unannounced audit. The latter audit split the audit requirements into two separate audits, the first one being announced and the second unannounced. Based on the idea that the full unannounced audit option gives extra confidence to the specifiers, Issue 6 will be in line with Issue 8 of the Food Standard by removing the split unannounced audit option. However, unannounced audits will remain optional.

Key Changes to the Requirements:

- Corrective and preventive action: fundamental clause. The version integrates requirements on corrective and preventive action related to root cause analysis into a structure continuous improvement approach. The newer version emphasises the importance of addressing issues with the intent to remove the risk of the same issues happening again, demonstrating continuous improvement. This is fundamental, therefore sites that have not implemented this clause cannot be certified by BRC.

- Product quality and safety. In BRC Packaging Materials Issue 6, there is emphasis on the importance of food safety culture being present at the site. A new clause is introduced to the issue which requires sites to set up, execute and review an action plan to improve product safety and quality culture. The auditor will not necessarily assess the culture of the business, but instead review the efforts made to document the status of the culture and the process put in place to maintain and improve good culture.

- Emphasis on product quality. Packaging materials is not just for hygiene, it covers both product safety as well as product quality. In the new issue there is emphasis on product quality and there is a clear difference between product safety and quality. The new issue separates hazards into product safety and quality defects to improve the necessary measures to prevent, remove and decrease each product quality hazard to acceptable levels.

- Pellet, flake and powder control in the plastic industry. Issue 6 acknowledges the importance of raw material management in the packing industry and intends to remove the risk of contamination from the food supply chain. This refers to the removal of risks caused by cumulative chemical contamination of the human food chain, removing the risks of starvation of fish and marine mammals.

BRC Packaging Materials Issue 6 – At a Glance

After the announcement of the new issue in August, there is a six-month transition period to allow time for businesses to prepare for audits under the new issue from February 2020.

If you have any questions regarding the new standard of BRCGS Packaging Materials, please submit an enquiry below or contact us on 0845 026 7745.