What is food traceability?

The Food Standards Agency (FSA) defines food traceability as the ability to help keep track of ingredients and finished food products in the supply chain, which supports a swift and accurate withdrawal/recall of unsafe food, if required.

Why is food traceability important?

Companies are being held more accountable for inventory transparency from where and how raw ingredients and finished goods are grown, manufactured, stored and distributed; this is why more companies are demanding their suppliers hold certifications such as BRCG and SALSA. A robust food traceability system will allow product withdrawals and recalls to be carried out quickly and efficiently, limiting the health effect on the general public, as well as minimising the financial and reputational damage to your company. For successful product withdrawals and recalls to take place, it is vital that everyone in the supply chain adhere to food traceability laws.

What UK law says?

In accordance with UK law you are required to have information on all your suppliers that provide you with ingredients and finished food products, and all business customers that you supply (in other words, one step back and one step forward).

If you are a retailer or caterer selling to the final consumer, you are not required to keep traceability records for sales to your customers. However if supplying to food businesses, all traceability requirements apply.

Enforcement authorities have the right to access your traceability records if required. So, the correct information should be recorded, and stored in an organised manner for files to be accessed quickly.

4 steps to creating a food traceability system

1. The system

Records must trace food/ingredients purchased from your suppliers and supplied to your business customers.

2. Defining batches of food

Creating a batch system will help manage your traceability, limiting the amount of products needing to be recalled or withdrawn if such a step needs to be taken. Minimising the impact on your business both financially and operationally.

3. Traceability information

The below information should be kept on both your suppliers and business customers:

- Business name

- Business address

- Description of foods purchased and sold

- Quantities

- Transaction dates

Businesses may also opt to store raw materials in their original packaging to display traceability information. However, the above information is still required.

Businesses that handle products of animal origin (POAO) or sprouted seeds must also comply with more specific food traceability requirements.

4. Record Keeping

Your records should be easily accessible at all times, in the event of a product withdrawal, recall, or authorities request. The speed at which information is retrieved will help minimise the scale of the withdrawal/recall and the impact on public health.

Traceability information for pre-packed food should be kept for a minimum of 12 months after the product’s shelf life unless there are additional legal requirements for the particular goods you are handling.

Top Tips

- Work with suppliers who take traceability seriously and have robust record keeping systems.

- Develop comprehensive internal systems and train staff thoroughly to ensure matching input and output. The Food Standards Agency offers a traceability course.

- Consider also keeping a history of batch numbers, invoices and receipts purchased food goods in addition to the basic information required by law. The more detailed records make for an easier and more successful withdrawal/recall, if required.

- Review your files annually to ensure they are kept up to date.

Difference between food withdrawals and food recalls

Food withdrawals

Discarding unsafe food from the supply chain; withdrawal occurs when the goods have not yet reached the end consumer.

Food recalls

Removing unsafe food from the supply chain, and advising consumers to return or dispose of the food in question.

UK law on food withdrawals and food recalls

If you believe that goods you have handled (no matter at what point of the supply chain) are either harmful to health, unsafe for consumption, or do not meet legal requirements, then you are required by law to either withdraw or recall the goods IMMEDIATELY.

The below stakeholders must be informed of the food safety incident immediately and advised on the actions that should be carried out.

- The food safety authorities

- Suppliers

- Business customers

- Consumers

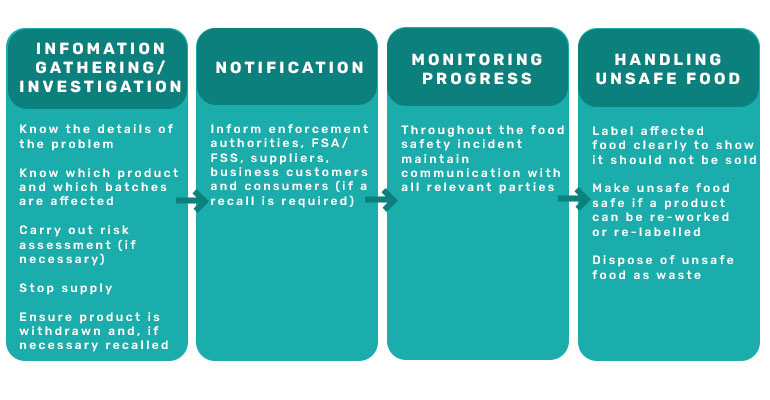

How to manage food withdrawals and food recalls

Food withdrawals and food recalls best practices

- Circulate communication materials such as Q&A for consumers.

- Follow up on business customers to ensure that they take the required steps.

- Monitor the progress of and closing a withdrawal/recall.

- Review the effectiveness of the withdrawal/recall so you know how much of any of the affected products could still be in the supply chain.

- Conduct a root cause analysis to discover how the food was contaminated, and implement procedures and checks to ensure that it doesn’t happen again.

Looking for help?

Complete Food Safety offers consultancy support on all aspects of food safety including food traceability. Contact us today for help and support.